Custom Laser Cutting Services

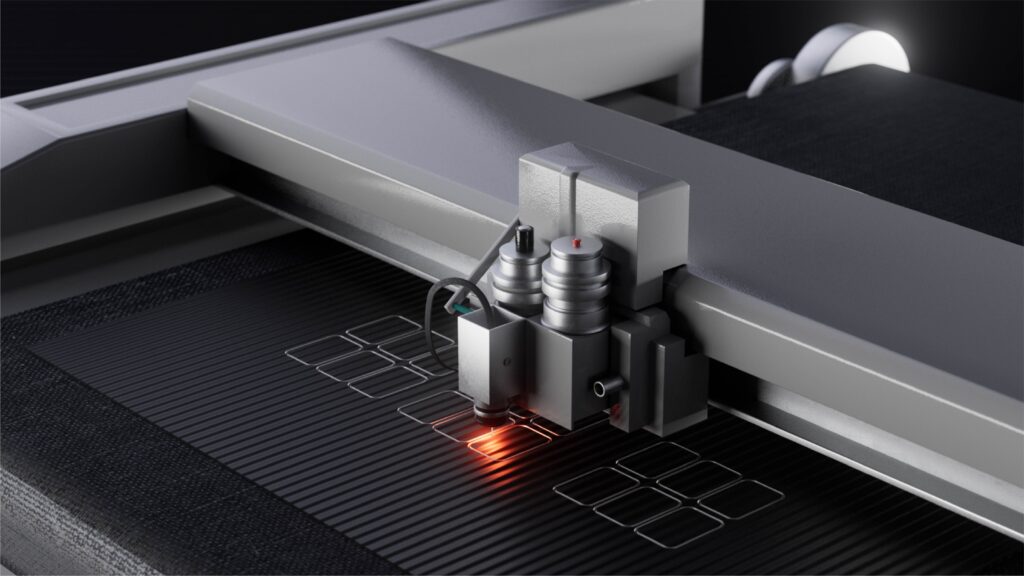

SRP’s laser cutting services are a great option for small and low-volume production runs. Laser cutting is also the go-to for rapid prototyping and part sampling. How does it work? Laser cutting uses software-guided fabrication, cutting design from the flat material with a laser beam. That means production can commence as soon as the material is available, making it a faster option than die cutting.

Why Custom Laser Cutting?

When SRP designs your production plan for your flexible thin-gauge components, we consider the performance of the material and your requirements, so you always get the highest quality results.

Speed

Laser cutting requires no custom-made die tooling, minimizing lead time for starting production. For rapid prototyping and quick-turn projects, laser cutting can provide a workable solution.Simplicity

After uploading CAD files of the design, the software-guided laser beam accurately cuts the shape from the material.Accuracy

Laser cutting can cut intricate shapes and small parts for jobs that require a perfect fit. There’s no blade or die that contacts material, so it’s particularly effective for thin-gauge material. Contact with the laser beam does not cause the material to stretch or shift.Considerations for Laser Cutting

Accuracy and speed make laser cutting an attractive option for fabricating your custom converter. In some materials and applications, however, laser cutting doesn’t produce the highest quality results. These are some of the factors SRP considers when considering whether laser cutting is the best fabrication method for your custom converted materials.

Finish and Edging

Depending on the chemistry of the material, high temperatures from the laser beam can cause burns and melting along the edges, the area known as the heat affected zone (HAZ). If a clean, finished kerf is critical to your product’s appearance and performance, materials with excellent thermal stability are the best candidates for laser cutting.Thickness

Production speed of laser cutting can vary, depending on material thickness and density. Thicker, denser materials are more difficult to cut, extending production time and increasing costs. Because thicker materials require longer cutting times, laser cutting can extend the heat affected zone.Material Type

Laser cutting is a highly accurate and repeatable cutting method for thin and flexible materials. In thin materials, laser cutting offers fast fabrication while keeping the heat affected zone to a minimum. Flexible materials best suited for laser cutting include adhesive, rubber, foam, sponge, Formex, Nomex, thin plastics and films.Material Chemistry

The material’s chemical and thermal properties are critical factors when using laser cutting to achieve your shape. Some materials and adhesives can emit toxic fumes, making it less ideal for thicker, denser materials.SRP laser cutting specifications

- Laser type and configuration: 150W CO2 Laser

- Best cutting material: Rubber, foam & adhesive

- Cutting thickness: up to .375”

- Accuracy (+/-) .010

- File formats: DXF, DWG, STEP, PDF

Why SRP converting services?

- SRP handles every step of production in-house, from proof of concept to shipping, offering our customers high visibility into the project status and flexibility.

- Trusted partnerships: We work closely with our longtime die-makers to ensure the quality and precision tooling the job demands.

- Quality control: We offer proof of concept with CAD technology as well as rapid prototyping to ensure design feasibility before committing to hard tooling.

- SRP is continuously seeking improvements to service, quality and expertise, making us the trusted producer of your custom converted parts.

- Our superior service and rapid response time provides exceptional value every time.

How can we help?

Please submit the form and a member of our team will be in touch with you shortly