Advantages of Thermal Interface Pads Vs. Thermal Paste

Thermal Interface Materials are a critical aspect in the design of electronic components, making the difference between a working product and a faulty product. The purpose of Thermal Interface Pads is to provide a preferential heat transfer path between heat-generating components like integrated circuit chips (CPUs) and heat spreaders such as a heat sink.

If you take a close look at the surface of a CPU or a heat sink, the surface will never be entirely even or level. There will be minuscule bumps, spaces and gaps between the two that will allow for air to pass through the components. Since air is not a good conductor of heat, these gaps have a very negative effect on the heat transfer.

Thus, a Thermal Interface Material with high thermal conductivity is needed to fill those gaps to improve heat conductivity between the CPU and heat sink.

What are thermal interface materials?

Thermal interface materials transfer heat from one surface to another. Ultimately, the goal is to dissipate heat generated from an electrical or mechanical component and into a heat sink, which is usually made of aluminum, copper or even ceramic. The heat sink is deeply ridged, creating air gaps between the ridges, creating an ideal format to dissipate heat.

Some thermal interface materials solve a common problem in machinery and electrical components. All too frequently, there are rough, uneven and wavy surfaces, making it difficult to establish the needed surface contact to create sufficient thermal conductivity to get it to flow away from the component. That’s when thermal interface materials serve as gap fillers. It’s specially cut and fitted to create a tight-fitting connection between the two elements, filling the air pockets with thermally conductive material.

Thermal interface materials connect the component, allowing the heat to flow from the component and into the heat sink. There are a number of materials and solutions to transfer this heat, but the two most common are thermal interface units and thermal paste.

How to apply thermal interface materials

Applying thermal interface pads

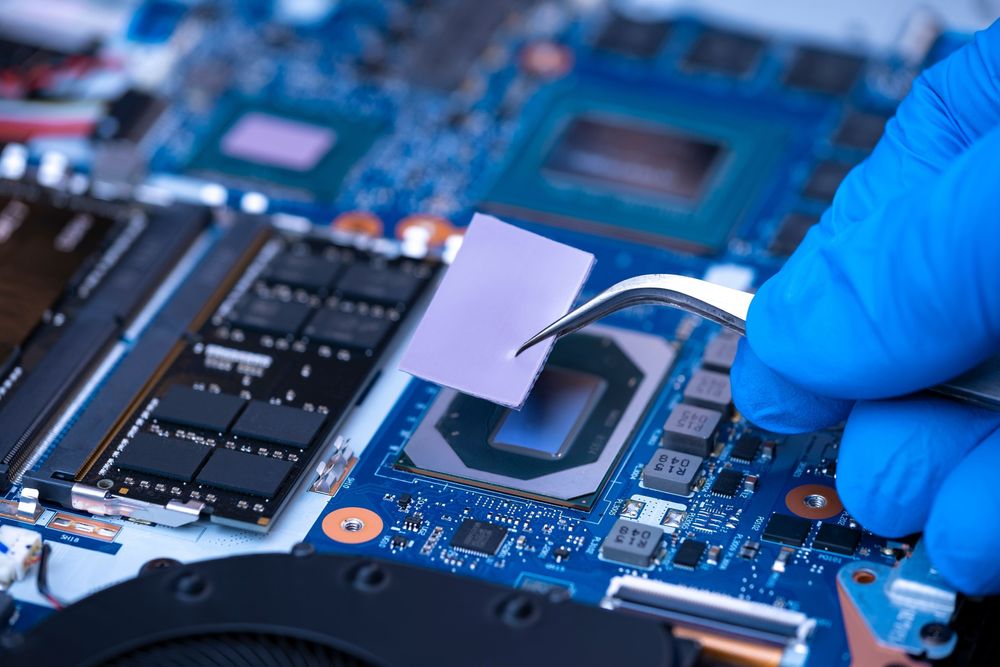

A thermal interface pad is most often a silicone pad joined to a heat sink. The silicone pad provides thermal conduction that transfers heat from the component to the heat sink. Applying the thermal pad is a simple matter of peeling the adhesive backing on the silicone and sticking to the silicone pad.

Applying thermal paste

Applying thermal paste is a matter of applying a thin line of thermal paste on one component, allowing the weight of the heat sink to spread the paste as you join the materials. Thermal paste is made of thermally conductive materials, such as metallic elements, ceramic or silicone.

Advantages of Thermal Interface Pads Vs. Thermal Paste

No Mess

Applying thermal paste can be a messy process. Thermal Pad installation is simply peel and stick.

Fills Bigger Gaps

Thermal Pads are available up to .25 inches, as opposed to the thin layer of thermal paste.

Even Application

Thermal paste takes skill and precision to apply evenly and in just the right amount. On one hand, you need enough coverage to conduct the heat. On the other hand, applying too much product would result in messes and waste.

Easier Installation

Thermal Pads can be custom die-cut to the exact specification of the component for a perfect fit, every time.

Conformity

Thermal Pads conform precisely to uneven and irregular surfaces to eliminate gaps. The silicone layer of the thermal pad becomes softer and more pliable in higher temperatures; by applying light pressure, you can achieve an even snugger fit.

Faster Assembly

Thermal paste has a curing process, which means there’s a wait for the substance to harden so the assembled item can be moved or handled. The curing that accompanies thermal paste adds time to the assembly and occupies work space.

Important Aspects to Consider When Choosing A Thermal Interface Material

When developing electrical components, the design and engineering teams should work closely together to determine key design and functionality factors:

- The amount of electricity that would be generated from the components

- Identify any gaps early in the design phase to prevent design changes down the road

Doing this could save a lot of time and money when it comes to prototyping and testing.

Application mistakes with Thermal Interface Materials

When using Thermal Interface Materials, steer clear of these common application errors.

- Never combine Thermal Pads and Thermal Pastes. Thermal Paste will reduce the thermal conductivity to pass through the Thermal Pad to reach the heat sink.

- Avoid stacking Thermal Pads. This will decrease the material’s performance. One Thermal Pad with the correct thickness and thermal conductivity rating is all that is required to solve even the most stringent application issues.

- If you ever remove a heat sink, the Thermal Pad will need to be replaced to properly conform to the surface. Be sure to remove any debris that may have entered the component as well.

SRP: BUILDING RELATIONSHIPS THROUGH CONVERTING SOLUTIONS SINCE 1951

SRP provides customers with everything from material sampling and product prototyping to full manufacturing, packaging and delivery. We provide value to our customers by delivering exceptional customer service, engineering solutions and quality products to meet their every need.

For more information, you can reach SRP at info@srpco.com or 847.593.5630.

Ready for a quote? Show us your design and we’ll get you an answer in less than two business days.