Converting materials, solving problems and exceeding expectations since 1951.

We deliver real-world solutions with intelligent answers, accurate timelines and excellent service.

Capabilities

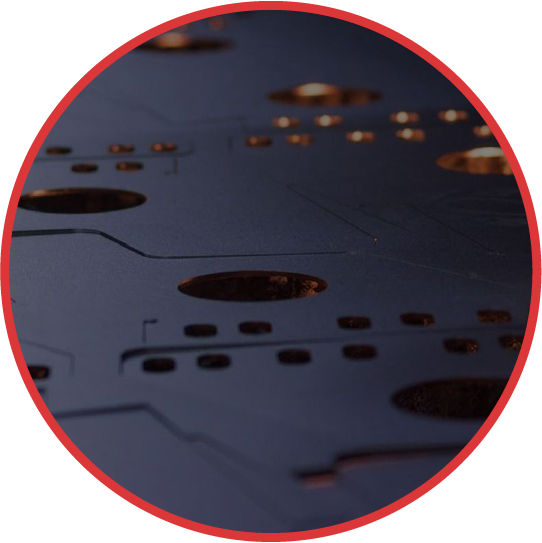

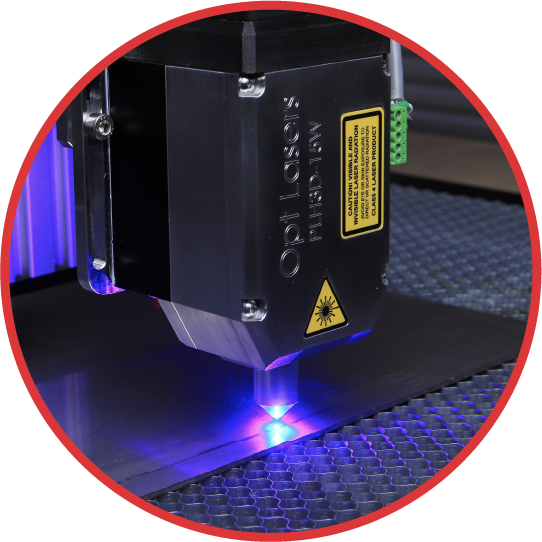

We invest in manufacturing technology that saves time and money on gasket fabrication — and we maintain exacting standards for quality. Our capabilities include:Industries

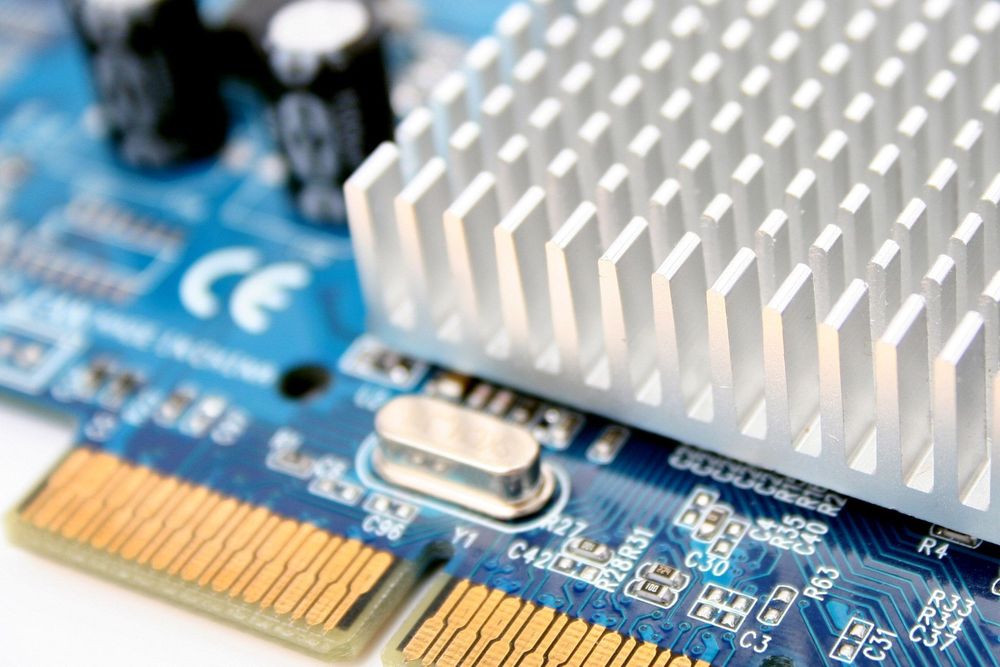

We provide high-quality converting services to a variety of industries, including:Custom Gasket Materials & Manufacturing

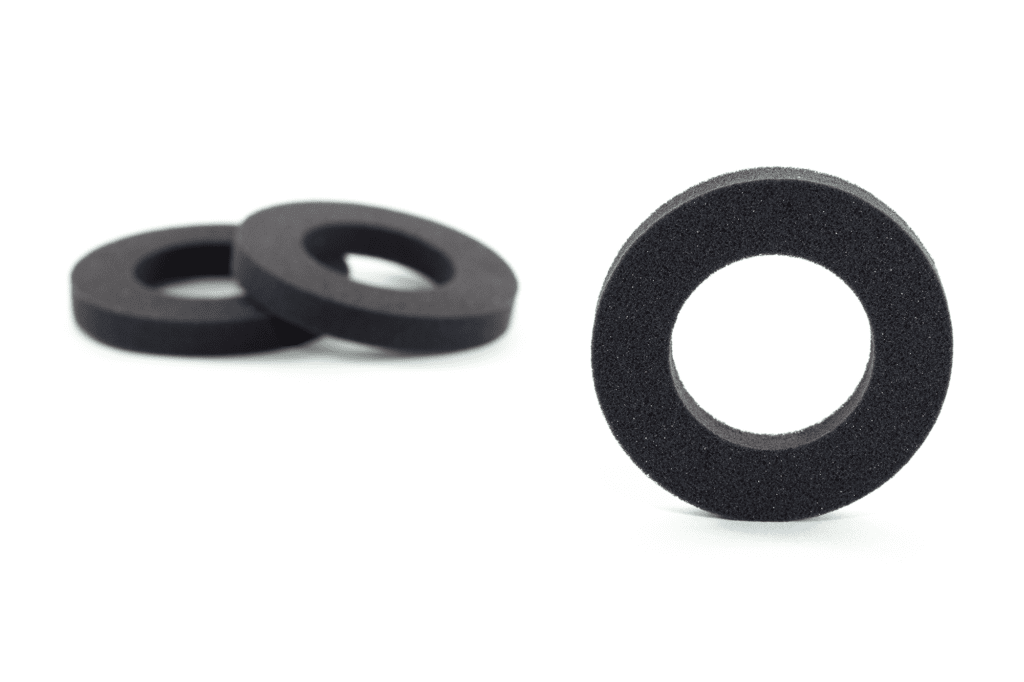

We can handle every aspect of your custom gasket project: sourcing, fabricating, assembling, packaging and shipping. We’re ready to start as soon as you have your design. We apply our knowledge of materials and applications to create custom gaskets that meet demanding requirements across industries.

Gasket Applications

We have the experience needed to solve your most difficult gasketing and sealing challenges. Here are some examples of gaskets we have made for other customers, using a range of elastomeric materials and adhesives. Browse by material or application — or contact us to get started.

Preferred Converters

We have earned preferred converter status with industry-leading suppliers and source our foam, silicone and adhesives directly from them. Each custom gasket is made with high-quality, proven materials at the best price possible.

Quality Focused, Precision Driven

Because we set high expectations for ourselves — improving processes, building knowledge and updating technology — we’re confident we can reach yours.

- We’re an ISO 9001:2015-certified facility

- We can meet Production Part Approval Process (PPAP), First Article Inspection Report (FAIR) and other quality control measures

Case Studies from SRP

Problem solved: Real-world examples of how we have helped other customers

How can we help?

Please submit the form and a member of our team will be in touch with you shortly