Rotary Die-Cutting Services

Highly repeatable, precise and versatile: SRP’s rotary die-cutting services make it possible to produce high volumes of identical parts from flexible material, while also meeting your most stringent tolerance standards.

The Benefits of Rotary Die Cutting

Great for high-volume projects as well as projects that demand an exact fit. SRP’s rotary die-cut services are one way we make gaskets that meet your expectations for excellent service, quality and value.

Efficient

Rotary die cutting dramatically reduces labor and material costs for high-volume runs. It can cut parts from multiple layers of foam, film and pressure-sensitive adhesives. Unlike cutting methods that use blades, water jets or lasers, rotary die cutting uses one single cut to remove material.Versatile

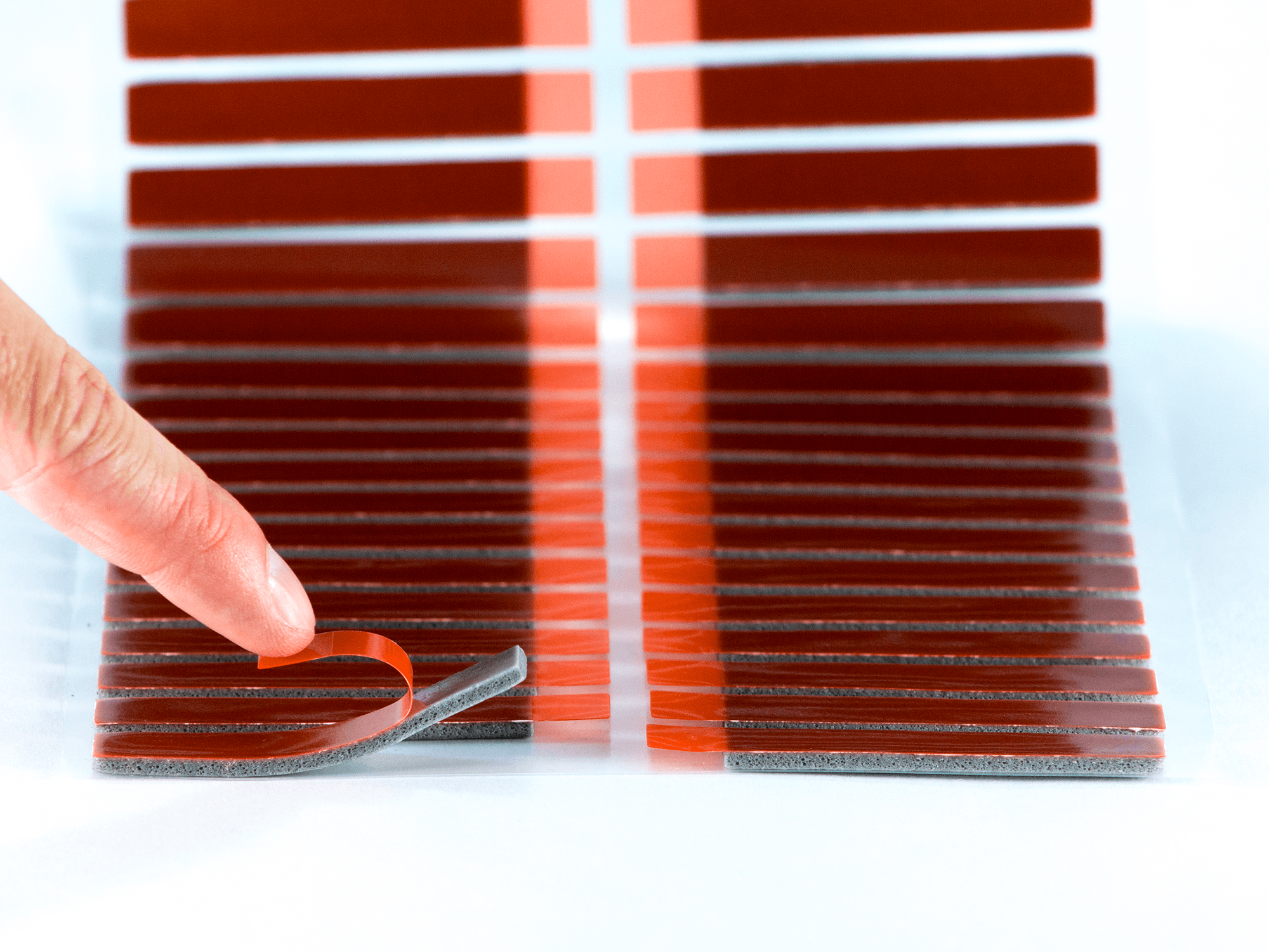

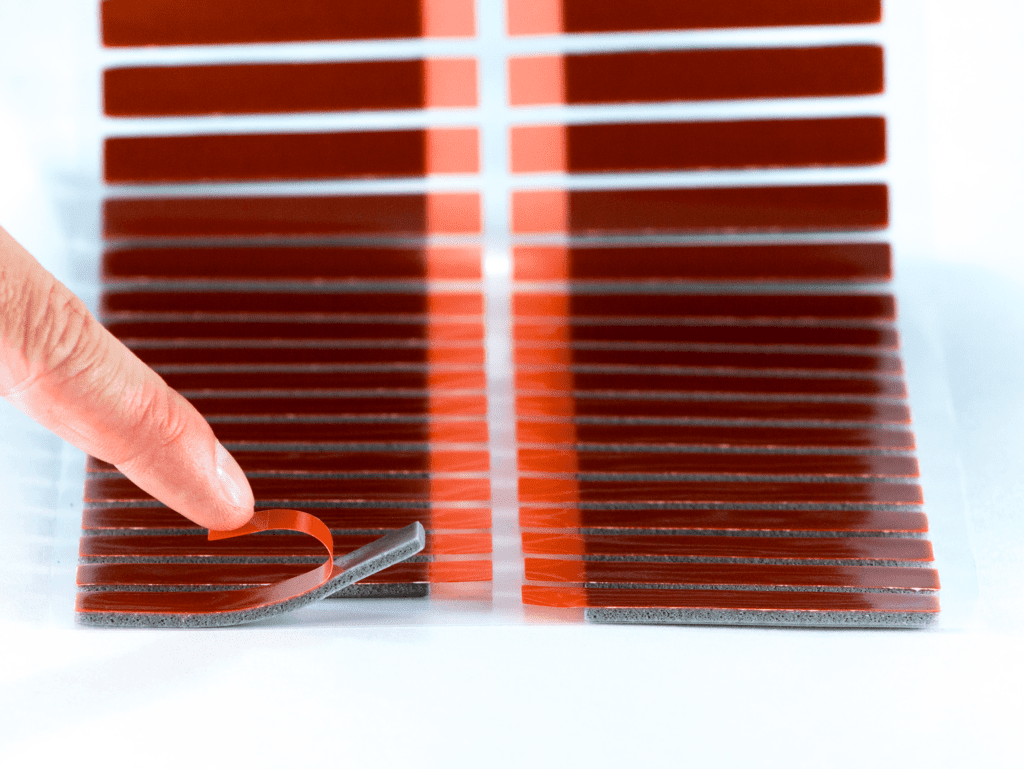

For easy peel-and-stick applications, rotary die cutting can also kiss-cut parts to a liner. It’s also capable of zoned adhesives for secure bonding in specific areas, and adding pull-tabs for quick and easy assembly.Precise

Die cutting is the way to achieve high-precision cuts and perfectly repeatable results from start to finish. The pressure from the rotary die prevents shifting and stretching during cutting, producing highly consistent parts that meet stringent tolerance requirements.Top Materials Used For Rotary Die Cutting

Rotary Die-Cutting Process: How It Works

Our customizable die presses stamp out unique cuts from sheets and rolls of non-metallic material at a higher throughput than most other fabrication methods.

The customized dies are fitted on a cylindrical anvil. So as the material is fed into the rotary die-cutting machine, it passes through the rolling die, which is pressing down on a hard substrate surface. As the die connects with the substrate, it completes the cut through the material.

Rotary die cutting offers a versatile, accurate and efficient fabrication process for your custom converter project. In addition to through cuts, it also makes kiss cuts and perforations.

Even in kiss cutting applications — where the cut may end at the liner, for example — rotary die cutting keeps wasted material to a minimum.

Rotary Die Cutting vs. Flatbed Die Cutting

What are the key differences between rotary die cutting and flatbed die cutting, and how does SRP choose?

What Is Flatbed Die Cutting?

The flatbed die-cutting method cuts shapes from materials using steel rule dies affixed to a flatbed powered by hydraulic presses. Here are some advantages:

- Less expensive tooling and dies

- It stamps out simple shapes quickly, making it ideal for general cutting.

- Fast changeover of the die makes it ideal for low-volume orders.

When Is Rotary Die Cutting The Better Option?

The precision and speed of rotary die cutting — with its custom die shape applied with the pressure of the rolling anvil — provides the best results for high-volume projects as well as projects that demand an exact fit, particularly in the medical, military and aerospace industries.

Why SRP Converting Services?

SRP’s rotary die-cut services are one way we make gaskets that meet your expectations for excellent service, quality and value.

As a preferred 3M Converter, we source top-quality materials at the best prices direct from the manufacturer. We use design of manufacturing that best meets your standards but is also the most efficient. We own the entire process from start to finish, from reviewing your initial design to shipping the final product.

How can we help?

Please submit the form and a member of our team will be in touch with you shortly