Waterjet Cutting Services

With SRP’s waterjet cutting capabilities, we make it possible to get precise cuts from flexible material that’s too thick or rigid for die cutting, and optimize material yields of your custom converted materials.

The Benefits Of Waterjet Cutting

Waterjet cutting can be a cost-effective option for custom fabricating low-volume orders, because it minimizes material waste while requiring no custom die tooling.

High-Quality Cuts

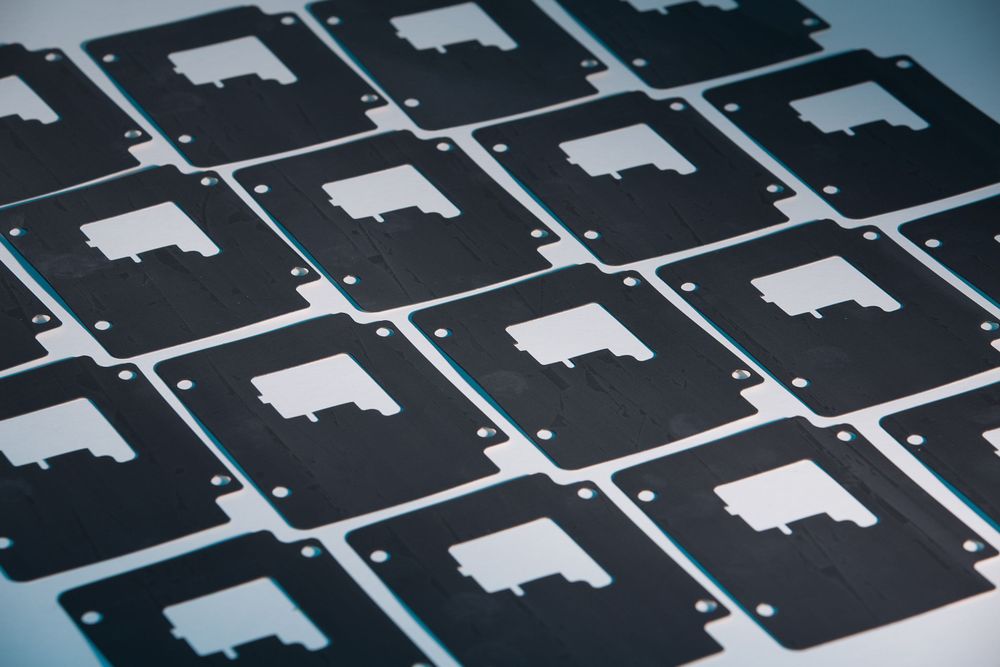

For thicker and more challenging material, waterjet cutting leaves no compression distortion that’s characteristic of die cuts, allowing for clean sharp edges and tighter tolerances. Waterjet cutting achieves a clean kerf, smooth finishes and maintains your most stringent tolerances.Maximized Materials

Waterjet is an excellent option for cutting nested shapes to reduce material waste. For jobs with multiple sized parts, we use nesting software to get the most parts possible from a unit of material.Faster Uptime

The waterjet tool is guided by software, eliminating the time and expense of creating custom die shapes. For rapid prototyping and low-volume orders with a tight turnaround, waterjet cutting is the ideal option.SRP’s Waterjet Cutting Services At a Glance

Waterjet cutting is one example of what makes SRP a versatile custom converter of flexible materials so we can achieve the results and performance you’re looking for.

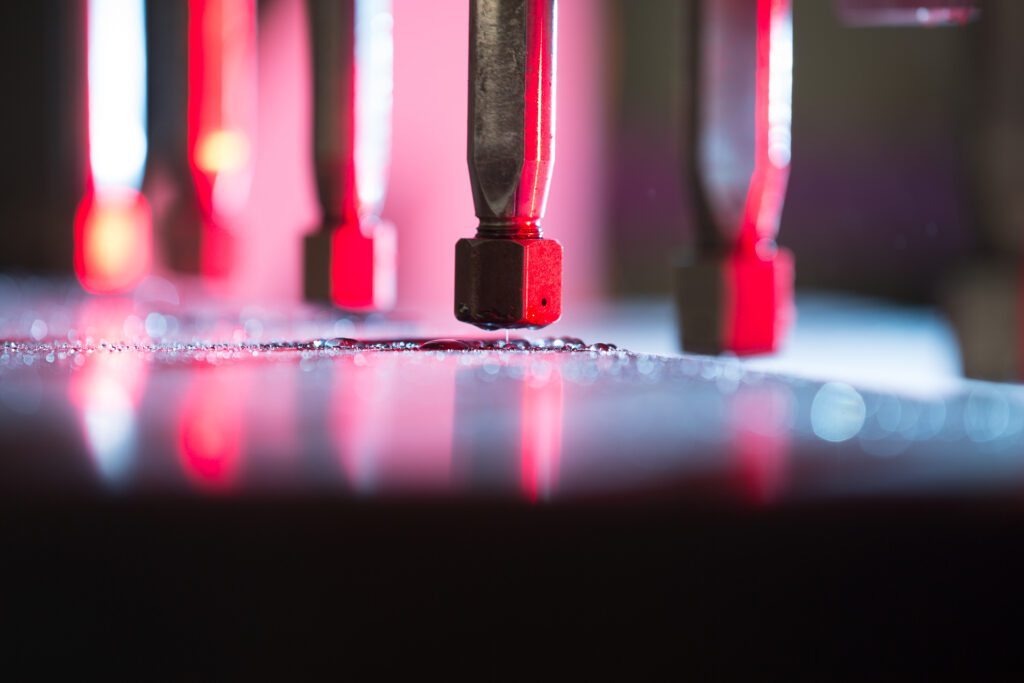

SRP’s waterjet cutter uses a tiny stream of pressurized water that travels more than 2.5 times the speed of sound. The nozzle is guided by a computer-assisted technology as the water stream makes a clean slice through the material. A CAD file with the final part design can be uploaded directly into the computer software to guide the precise measurements.

Which CAD Files Does Waterjet Cutting Support?

- DXF

- DWG

- STEP

Common Materials For Waterjet Cutting

- Foam

- Rubber (up to 1″)

- Sponge

- Plastics (acrylic, polycarbonate, Teflon)

Specifications For Waterjet Cutting

- Cutting Thickness: Up to 4″ (depending on material density)

- Cutting Length: 4′

- Cutting Width: 8′

- Standard Tolerances: +/- .010″

Why SRP For Gasket Fabrication?

At SRP we invest in technologies like waterjet cutting so you can get the better quality custom fabricated gasket without the high prices.

How can we help?

Please submit the form and a member of our team will be in touch with you shortly